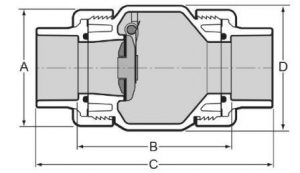

caption id=”attachment_310″ align=”aligncenter” width=”993″] Clear Body PVC Swing Check Valve.[/caption]

Clear Body PVC Swing Check Valve.[/caption]

ENGINEERED FOR MAXIMUM FLOW, QUICK RESPONSE & POSITIVE SHUTOFF

MOUNT EITHER HORIZONTALLY OR VERTICALLY FOR UPWARD FLOW

AVAILABLE IN IPS SIZES 1/2″ TO 4″

A Perfect Fit for Grey Schedule 80 PVC pipe.

Made from high visibility clear PVC.

Chemical & corrosion resistant.

Swing check has no metal parts.

Spring assisted model has stainless steel spring for positive closing & elimination of chatter.

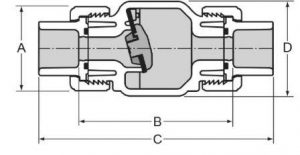

True union design for easy in line replacement or cleaning of sealed valve chamber.

Strong Spears buttress threaded union nuts.

Long life, high grade EPDM seat.

Weighted disc for tight seal independent of orientation.

Screens for foot valve applications.

Suitable for vacuum service.

Swing check opens with a pressure less than 4 KPa.

Pressure rated to 1034 KPa full flow open, 517 KPa back pressure closed, at 22ºC.

NSF Certified for potable water use.

Silicon free assembly.

![]()

Made in the USA by SPEARS MANUFACTURING.

CONVERT ANY PVC BALL OR SWING CHECK VALVE WITH IPS SOCKETS TO A FOOT VALVE WITH THESE ROBUST SCREENS

TEMPERATURE PRESSURE RATING FOR SWING CHECK VALVES

| SYSTEM OPERATING TEMPERATURE °C | 38 | 43 | 49 | 54 | 60 | 66 | ||

| MAX PRESS KPa | SIZE 1/2″ to 8″ | MATERIAL PVC | 1000 | 930 | 760 | 520 | 340 | 0 |

Swing check valves are designed for horizontal installations, but may be installed in up flow only vertical position. Check valves must be installed with the flow arrow moulded in the valve body pointing in the direction of flow. Do not install the valve upside down. Flow velocity should not exceed 1.5m/sec. Minimum opening pressure less than 4KPa.